Our team at Evatron Plastic Enclosures Ltd have extensive knowledge of enclosure products and the best way to achieve a great looking, functional product for our customers utilising modification services at our disposal. We are committed to supplying the best possible product to each of our customers and so you can be confident if you come to us with a challenge we will do our utmost to deliver an effective solution.

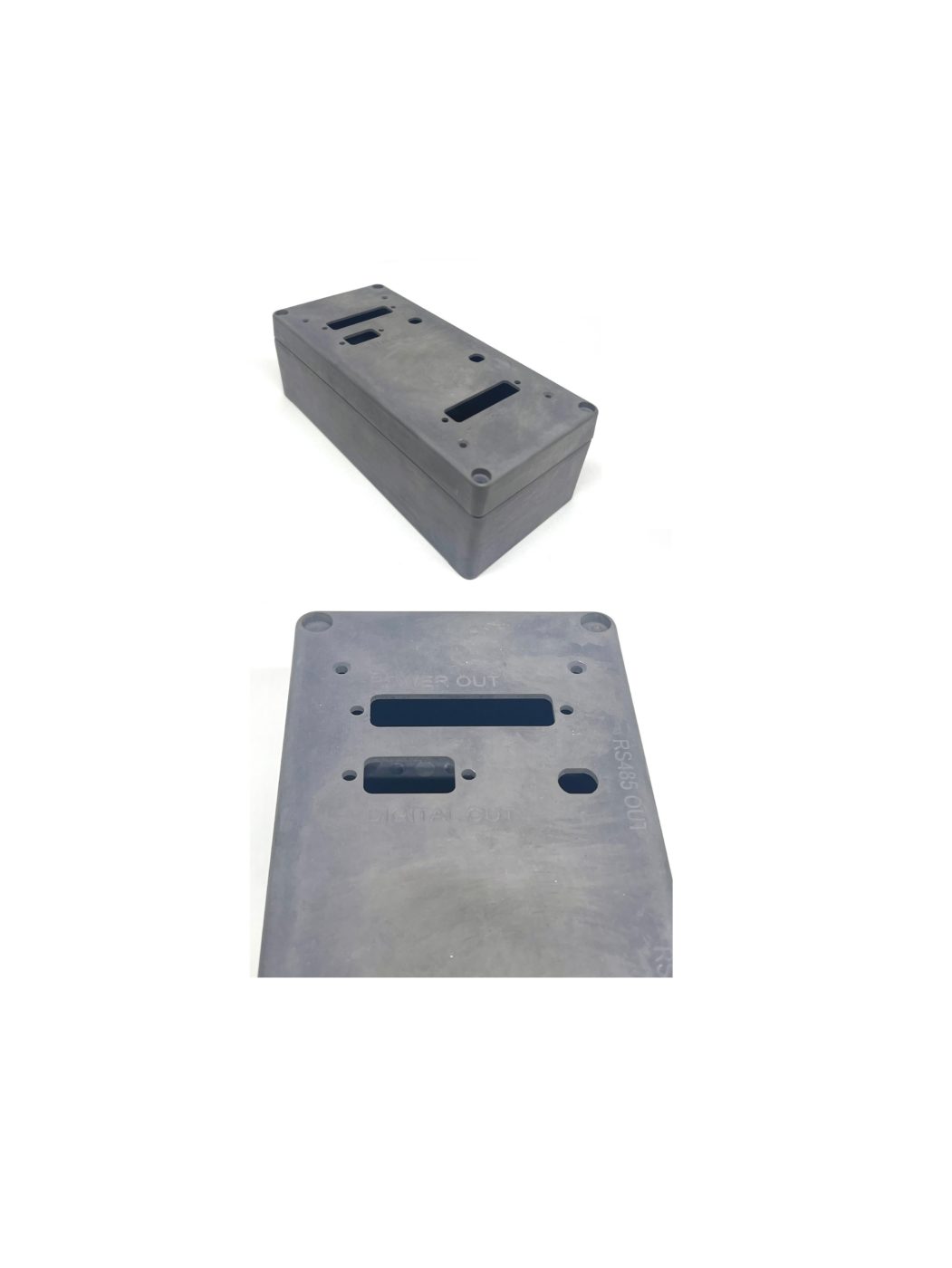

In July 2022 we were presented with a diecast aluminium enclosure that had been modified to the customers specification, it was clear to us and the customer that this enclosure was not fit for purpose. Whilst the machining was perfect, the “black” finish achieved with anodising and the engraving were far from up to scratch.

After inspecting the modified enclosure we noted the lid of the diecast box had a slight dome effect which had left the customer with areas of their engraving which were visible as intended in the high spots and unfortunately areas where it was barely visible in the low spots. We established that in order to achieve an effective finish there were two options available, firstly we could set a CNC machine to level the top face of the enclosure before proceeding to engraving however this would reduce the wall thickness of the custom enclosure and potentially cause assembly issues with the chosen components. Secondly, we could opt to use screen printing to add the required text to the IP66 enclosure, this method would retain the specified wall thickness and application would not be limited by the uneven lid finish. We demonstrated both options to the customer along with some images from previous orders and screen printing was selected as the finish option.

The diecast aluminium enclosure had been anodised but unfortunately looking at the colour and powdery finish it was very quickly established that this method was simply not suitable for the material. We suggested that painting the aluminium enclosure black with a low gloss paint would create a hard wearing finish whilst delivering the appealing aesthetic they needed for their product. We discussed RAL colours with the customer, sent images of previously completed IP rated diecast enclosures and jet black (RAL9005) was selected to complete the metal enclosure.

Once the plan was in place, we continued to machine, paint and screen print to the new brief all within a 2 week lead time in order to minimise production down time for the customer. We take great pride in listening to a customer challenge, fully understanding their brief and subsequently delivering solutions to very happy customers.

If you have an upcoming project and would like some guidance about the best way to achieve the best results please do no hesitate to contact a member of our team. We can undertake a wide range of modification services including CNC machining, Painting, Screen Printing, RFI Shielding, Engraving and custom moulding/custom sheet plastic fabrication. Our team are available to email sales@evatron.com, by phone 01908 325100 or using our Live Chat service.