How to specify your enclosure product.

There are many variables that should be reviewed when specifying your enclosure product, taking the time to read our tips should stand you in good stead.

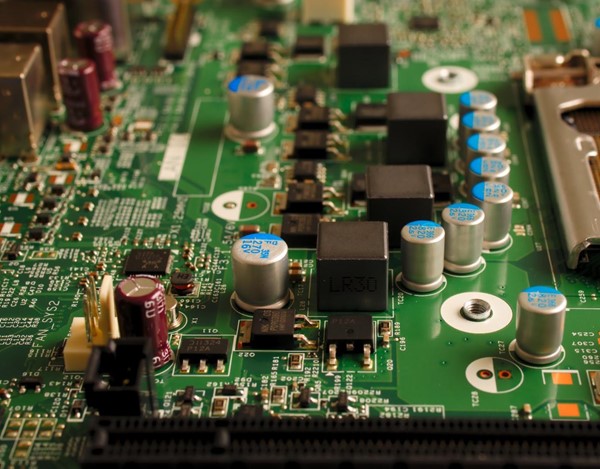

Identifying the potential size and layout of your PCB should be one of your first considerations, the best approach is to develop the PCB with some enclosure products in mind. This flexible approach to the design will allow you to take advantage of the enclosures features such as PCB mounts moulded into the enclosure and adapting the board to fit the box means all the internal space can be utilised. Planning the PCB layout and suitable mounting points around an enclosure in the design stage will also allow you to best position any apertures for connectors and cable entry points. If the board design has completed before an enclosure has been identified you may find it difficult to find an enclosure that fits the board, which may mean you’ll have to compromise on the size and subsequently select a product larger than you need or even have to redesign the board.

The application environment raises questions about the product you should use. Will the product get wet, be exposed to sunlight for extended periods of time or subject to impact?

Ingress Protection

You should ensure that your electronics are protected against ingress including human contact, tools, dust particles and liquids. Taking time to examine the potential exposure and referring to an IP rating chart when specifying your enclosure will help to choose a product with adequate protection keeping your electronics safe.

Material

All materials have their own strengths and weaknesses, and therefore choosing the right material for your product is also an essential step to ensure long product life and keep your electronics protected. If your product is to be situated in low or high-temperature environment take some time to view the material specification provided by the manufacture which will indicate the temperature variants the enclosure can withstand. Materials such as steel and diecast aluminium are commonly used for their superior strength. Enclosures manufactured in these materials are often used when impact is a risk. The level of impact protection a product has is indicated by the term IK rating, referring to an IK rating chart and to the material specification supplied by the manufacture should help you select a material suitable for the application.

Radio interference and Electromagnetic interference generated by other devices can also play a part in your material selection, if the operation of your product is likely to be affected you will need to select a material that can block out external interference, typically metal products offer high protection without modification. Plastic offers low protection against this interference and you will need to use an internal protective coating to shield your product from the interference. The end result of the coating is effective however it is worth factoring in this additional operation when comparing costs of similar plastic and metal enclosures.

For external projects the UV stability should be scrutinized as long exposure to ultraviolet radiation can lead to some plastic material to discolour or begin to degrade. Materials such as polycarbonate have a good resistance to UV degradation however ABS material can be used if a UV stabiliser is used in the moulding process, this material information should be readily available from your chosen enclosure manufacturer.

The enclosures appearance will ultimately be one of the biggest deciding factors. For some installations that are not customer-facing the appearance is not likely to cause concern however for products in the public eye getting the right looking product is imperative. This is another argument for identifying enclosures that match the desired aesthetics before the board design is finalised and removing the need to compromise later.

Custom Enclosures

In some instances, it may not be possible to design the board around existing enclosure products and custom options will need to be considered. Designing and manufacturing your own enclosure will ultimately lead to the most flexibility however the same questions surrounding ingress protection, material and environmental factors should still be asked to create the perfect housing for your product. For further information on specifying your enclosure product, give us a call on 01908 325100 of fill in this contact form.