Plastic Fabricated Enclosures

Create high-quality, low-volume enclosures without tooling costs using our plastic fabrication service.

Create high-quality, low-volume enclosures without tooling costs using our plastic fabrication service.

🎄 Our office will be closed from Tuesday 23rd of December from 5PM and will re-open on the 5th January 2026 at 9AM, our last despatch day for UK orders will be the 22nd of December. All orders and emails received during this time will be processed and answered upon our return.

From all of the Evatron team we wish you a Merry Christmas and a Happy New Year. 🎄

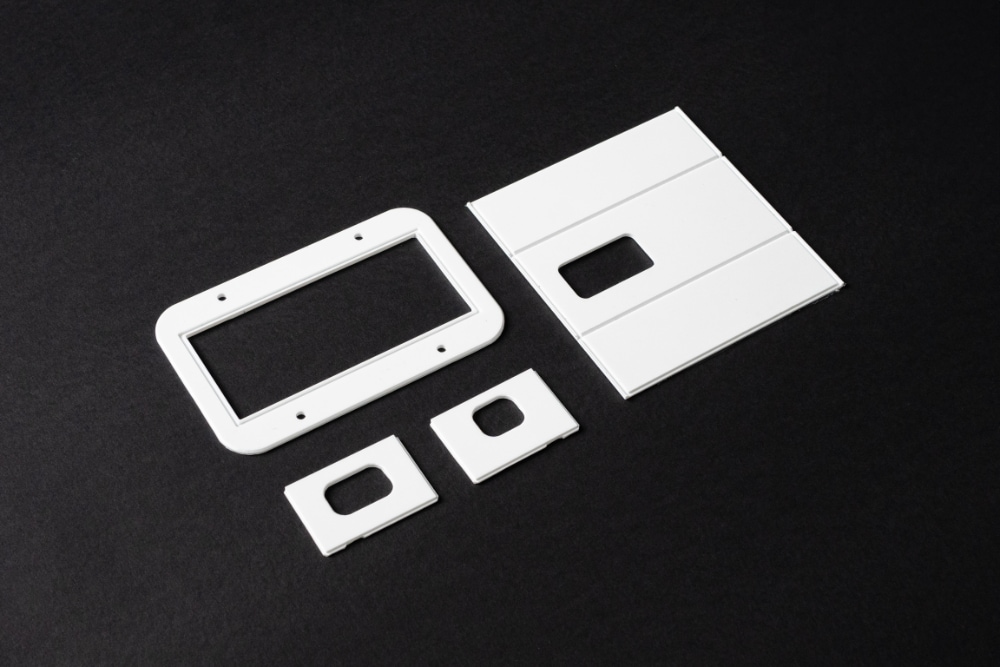

Evatron offers a plastic fabrication service, providing a cost-effective solution for low-volume production of unique enclosures when an off-the-shelf model is not available. Utilising tool-free manufacturing, enclosures are created from sheet materials that are cut, folded, and bonded to form durable, high-quality housings.

This custom enclosure system is a popular alternative to injection moulding, as it eliminates the time and cost of tooling. Typical lead times are around 3-4 weeks from design to delivery, with zero tooling costs.

Discuss your design requirements with our team, including material selection, sizing, and assembly needs. Depending on complexity, CAD files may be required, but we can also work from simple sketches or create enclosures to fit around an assembled PCB.

Before manufacturing begins, the design will be finalised between Evatron and the customer. For complex projects, a sample may be provided for approval. At this stage, material specifications—including temperature resistance, flame retardancy, and colour—will be confirmed.

Once the final design is approved, we begin manufacturing. Each enclosure segment is cut from large plastic sheets, including any required holes for components. At this stage, artwork such as logos and labels can also be applied.

With all components prepared, our manufacturing team assembles the enclosure by folding and bonding each segment to form the final shape.

Your designs will be securely stored for repeat orders, and thanks to the tool-free approach, future modifications can be made quickly and easily.

Contact us – sales@evatron.com

Custom enclosures tailored to your needs

From simple modifications to full designs, we create enclosures to fit your needs.