When it comes to electronic product design, one question continues to divide engineers:

Should you design your PCB first and then find an enclosure to fit, or select the enclosure before finalising the PCB layout?

Both approaches have their merits, but choosing the right strategy early can save significant time, cost, and frustration later in the development process. At Evatron, we work with engineers across multiple sectors, and here’s what experience has taught us.

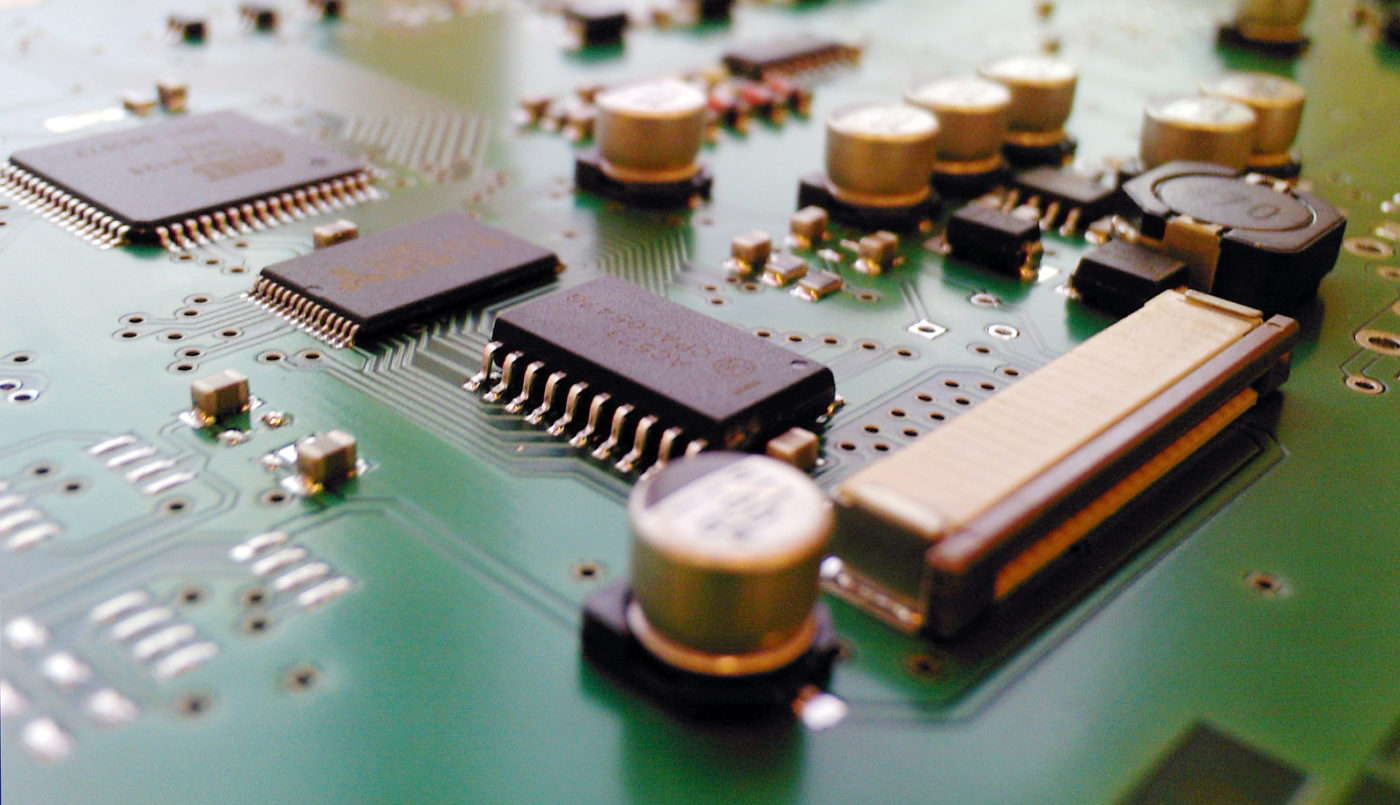

Designing the printed circuit board first is common in fast-paced development cycles. Engineers focus on component placement, signal integrity, and performance before considering the mechanical housing.

Pros:

Cons:

When to choose PCB-first:

If the project is highly performance-driven or your enclosure will be completely bespoke, PCB-first may be suitable. Evatron can assist to find suitable off the shelf enclosures for all shape and size PCB, in addition our tool free manufacturing service can be utilised to create completely custom enclosures with short lead times.

Starting with the enclosure means defining the product’s external dimensions and mounting constraints early, then designing the PCB to fit inside.

Pros:

Cons:

When to choose enclosure-first:

Ideal for consumer products, IoT devices, or any application where size, ergonomics, and durability are critical.

In reality, the most successful projects integrate mechanical and electronic design early and in parallel. This approach enables:

Modern CAD and enclosure customisation services make this easier than ever.

How Evatron Can Help

At Evatron, we offer a wide range of standard and customisable enclosures, combined with expert advice. Whether you’re starting from a blank PCB or working to strict housing dimensions, we can help you achieve a seamless fit.

"*" indicates required fields